އީމެއިލް ހުސް ނުކުރެވޭނެ

ޕާސްވޯޑް ހުސް ނުކުރެވޭނެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް މިހާރުވެސް އެބައޮތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް އެއް ނެތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

ހަބަރުތައް

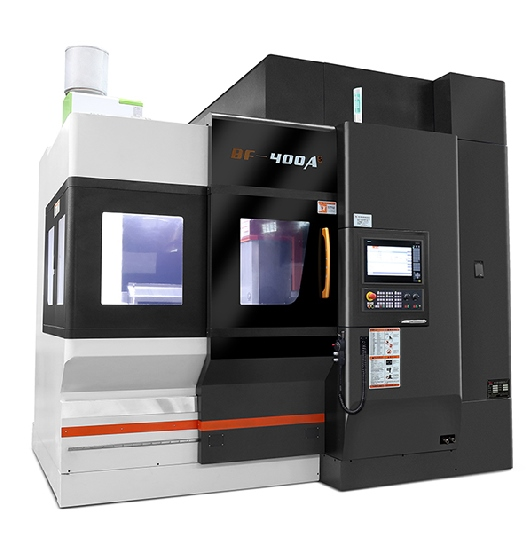

Choose a Suitable 5 Axis CNC Machining

When we talk about the 5 axis CNC machining center, the first thing we think of is the screw machine and complex exquisite parts. The 5 axis CNC machining center is more efficient because its operation mode is more complex and flexible. 5 axis CNC machining center is one of the types of CNC machining centers, which meets the special needs of CNC machining. Next, around the 5 axis CNC machine and its advantages and disadvantages, I will take you to have an in-depth understanding of the processing mode of the 5 axis machining center.

What is 5 axis CNC machining?

First of all, the machine of 5 axis CNC machining center is not as complex as expected. It has five axes, namely x, y, Z, and two rotating axes. Due to the different characteristics of rotating shafts, 5 axis CNC machine tools can be divided into the following types:

- When there are two rotating shafts on the tool, it can be a double swing head and a drooping swing head.

- When there are two rotating shafts on the workbench, it can be divided into two types: double rotating workbench and drooping workbench.

- When one rotating shaft is on the tool and the other rotating shaft is on the workbench, it can be divided into one swing and one rotation.

Five reasons for choosing 5 axis CNC machining center

- Be able to maintain the best cutting state of the tool

When we need to process a workpiece with an irregular plane, we need to rotate the workbench in different directions many times. Each rotation, the contact between the part and the tool is a perfect cutting, so that the 5 axis, CNC machining center can obtain better surface quality.

- It can process complex parts and effectively avoid the production of special tools

For some structural and functional parts and other high-precision parts used in the aerospace field or ships, ordinary three-axis equipment cannot meet the special processing requirements, but 5 axis equipment can meet such requirements, effectively avoiding the production of special tools. For CNC machining centers, this is to reduce the cost of tools.

- It can reduce processing technology and clamping times

Each direction on the workpiece has dimensions and tight tolerances associated with other directions. There is a risk of mistakes every time you re-clamp. For example, if a CNC machining center wants to make an aluminum part with five irregular sides, it needs to be manually clamped four times when using three-axis equipment, which means that four times of clamping will have four opportunities for scrapping, and the time cost will also increase, and the tools used between repetitions are also required each time. However, if the CNC machining center uses 5 axis equipment to process this part, there is no need to worry about these problems in terms of clamping and tool selection. This also shows that fewer fixtures can be used; Less plant area and maintenance costs to complete more efficient and high-quality processing.

- It can simplify production management and improve work efficiency

5 axis CNC machining center can achieve complete processing, greatly shorten the production process chain, and simplify production management and planning, and scheduling. The more complex the workpiece is, the more obvious the advantages of its production method will be.

- It can shorten the research and development cycle of new products

The 5 axis CNC machining center can solve the machining accuracy and cycle problems encountered in the research and development of new products, greatly shorten the research and development cycle and improve the success rate of new products.

Make a purchase of 5 axis cnc machining wood, smallest 5 axis cnc, 5 axis cnc machine shops from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.