އީމެއިލް ހުސް ނުކުރެވޭނެ

ޕާސްވޯޑް ހުސް ނުކުރެވޭނެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް މިހާރުވެސް އެބައޮތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް އެއް ނެތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

ހަބަރުތައް

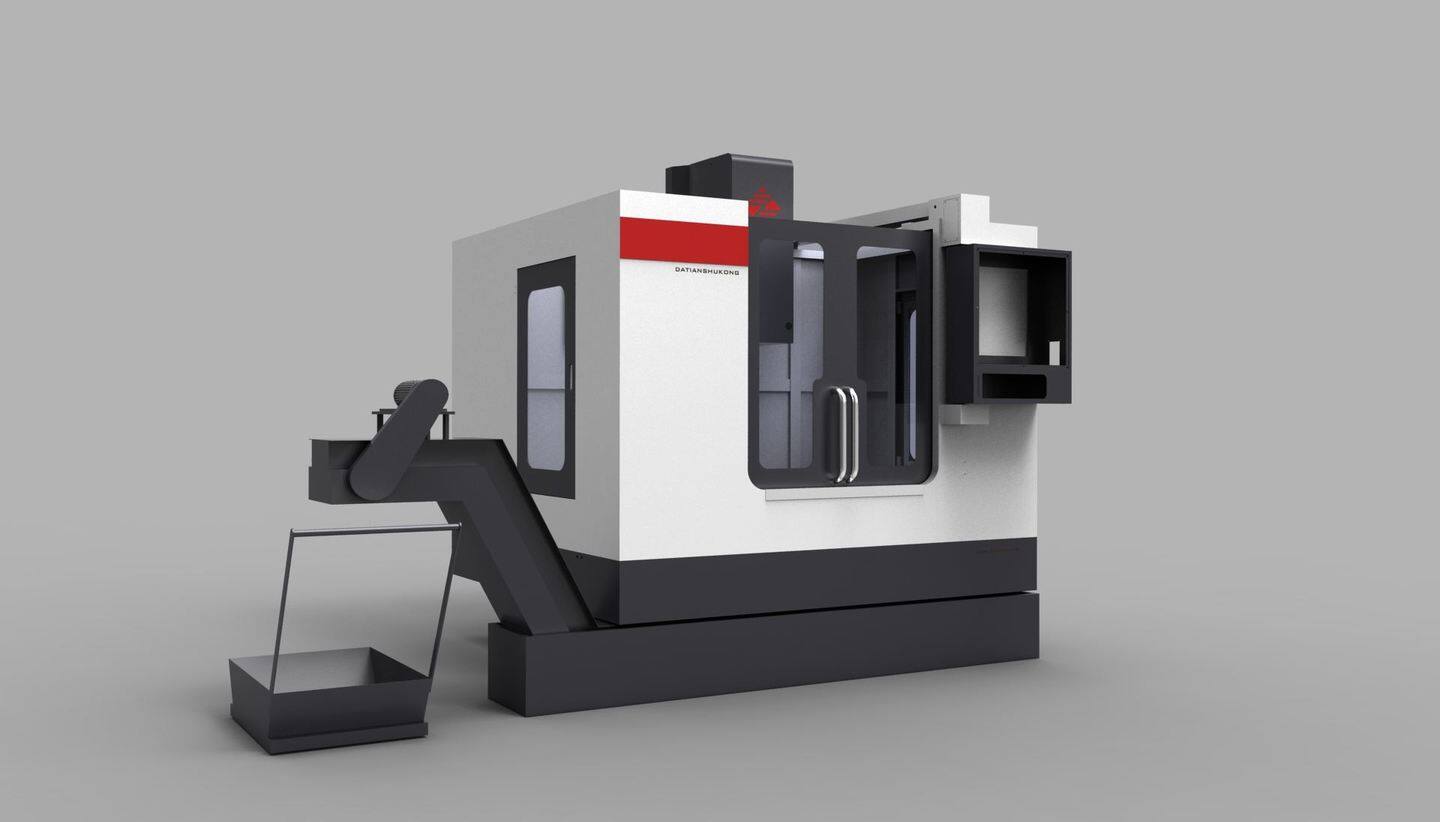

CNC Milling Machines and CNC Machining Centers

When the CNC machine tool carries out machining operations, the machining program must be written to control the CNC machine tool. The part processing program includes the relative motion path between the tool and the workpiece on the machine tool, process parameters (spindle feed speed, etc.), and auxiliary motion. The part processing program is stored in the program carrier in a certain format and code, such as a perforated paper tape, a cassette tape, a floppy disk, etc., with a certain format and code. The program information is input to the CNC unit through the input device of the CNC machine tool.

Numerical control is commonly used in machine tools. Numerical control is defined as a form of programmable automation in which the process is controlled by numbers, letters, and symbols. In the case of machine tools, this programmable automation is used for machine operation. Numerical control technology can be applied to a variety of operations, such as drawing, assembly, inspection, sheet metal processing, and so on. But it is more prominently used in various metal processing processes, such as turning, drilling, milling, forming, etc. In this paper, the composition of the CNC milling machine and CNC machining center will be briefly introduced.

Composition of CNC milling machine

CNC milling machines are divided into the general type and full function type according to their functions.

- Main movement: the main movement of the mechanical transmission device, including spindle, belt, and spindle box; Spindle electric drive device, including spindle motor and spindle driver. The CNC system processes the input command data and outputs control signals to the spindle driver. The spindle driver indicates the start, stop, and variable frequency speed control of the spindle motor. In the multi-function CNC milling machine, besides the speed control, the spindle orientation and positioning control are also available.

- Feed movement: the feed motor drive includes x-axis and z-axis ball screw pairs, guide rails, sliding blocks, etc. The feed electric drive includes x-axis and z-axis servo motors and servo drivers. The numerical control system processes the data of the input command and outputs the control signal to the servo driver. The servo driver drives the servo motor to drive the ball screw so that the sliding block can realize the feeding movement along the X-axis and the Z-axis. Finally, the tool can move relative to the workpiece according to the motion path and speed specified in the machining program.

- Auxiliary functions: the basic auxiliary functions of the CNC milling machine include cutting fluid switch control, lubrication control, tool change control, spindle box shift control, etc. For multi-function CNC milling machines, auxiliary functions include hydraulic tailstock control and hydraulic chuck control. The auxiliary functions are completed by the i/o modules, relays, contactors in the PLC of the numerical control system and the electrical control cabinet, as well as various detection switches and gas-liquid solenoid valves on the side of the milling machine according to the control logic.

Composition of CNC machining center

The spindle unit is installed in the spindle box and driven by the spindle motor through the drive belt. The spindle driver receives the control signal from the CNC system and drives the spindle motor to realize variable frequency speed regulation, start-stop and quasi-stop.

The fore-and-aft movement and spindle box x-axis, Y-axis, and z-axis ball screw servo motors realize the control signals of the left-right movement of the milling machine workbench and the up-down movement of the saddle; Receive servo drive CNC system and drive x-axis, Y-axis, and z-axis servo motors.

In addition to the basic auxiliary functions such as lubrication and cooling, the machining center also has two important auxiliary functions: one is the control of the tightening tool in the spindle; The other is the tool selection of tool inventory and tool mechanical tool change control.

Searching for a best desktop cnc milling machine, steel cnc milling machine, personal cnc milling machine manufacturer from China, you can get high-quality products at a nice price.