އީމެއިލް ހުސް ނުކުރެވޭނެ

ޕާސްވޯޑް ހުސް ނުކުރެވޭނެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް މިހާރުވެސް އެބައޮތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް އެއް ނެތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

ހަބަރުތައް

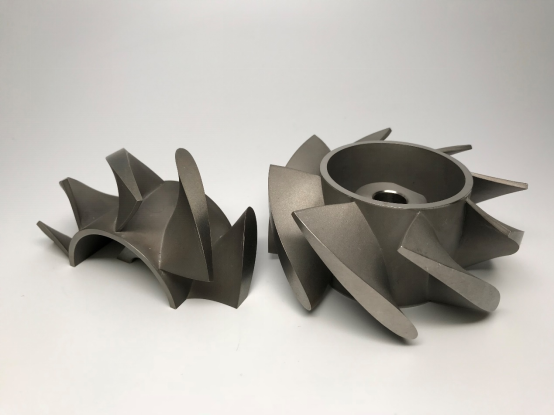

Precision Casting Parts Manufacturer, Supplier

At present, precision casting is widely used in many fields. In addition to general industrial machinery spare parts, it has been extended to the automobile industry, electronic and electrical, communication machinery, office automation, medical devices, and other industries.

There is a high-quality demand for spare parts in the above fields. In the general manufacturing activities of industrial machinery spare parts, precision casting, as a representative manufacturing technology in the rough industry, has attracted special attention.

As a professional precision casting parts manufacturer, today we will talk about the advantages, disadvantages, and cleaning methods of precision castings.

Advantages of precision casting parts

Compared with other processing methods of blank processing: machining, powder metallurgy, die casting, forging, injection molding, powder metallurgy, pressure casting, and other processes, precision casting has many advantages:

- The complexity of part shape is high;

- It can be applied to all kinds of alloy materials. The quality of auto industry spare parts requires more product appearance accuracy, internal defects, and mechanical properties of castings, and its quality and accuracy can be compared with the aircraft machinery manufacturing process.

Electronic, electrical, and communication machinery have requirements in electrical, radio wave, and magnetic characteristics. At the same time, the products in these fields are also required to be small and lightweight. In addition, the casting shape is complex and the thickness gap of the casting is large, which makes the casting of the above industries more and more difficult. In particular, the demand for aluminum alloy castings in these fields is large, and the overall functional requirements, large-scale and thin-walled lead to lighter casting weight.

It can be said that all fields have high requirements for the quality of precision castings and strict requirements to prevent casting defects. Therefore, it is particularly important to improve the production efficiency of castings while improving the yield.

Disadvantages of precision casting parts

Rough surface. Sand inclusion, slag inclusion, shell cracking, insufficient pouring, pinholes, pores, bubble beans, binder penetration, cold shut, breakout, shrinkage, black spots, out of tolerance of size, deformation, out of tolerance of weight, etc.

Almost all these defects are related to the mold shell. It can be said that mold shell manufacturing technology is the key to determining the quality of precision castings.

How to clean the precision casting parts?

The cleaning of precision castings can be divided into dry cleaning and wet cleaning. Shot blasting is the main method of dry cleaning. Wet cleaning mainly solves the problems of hydraulic sand and water sand.

The dry cleaning method is mainly through shot blasting to carry out friction treatment on the surface of precision castings. In short, the shot blasting is driven by compressed air, so a certain speed is sprayed on the surface of precision castings to remove sand particles and iron oxide on the surface. However, due to low efficiency, uneven cleaning, and poor effect, many manufacturers do not accept this friction cleaning method because of its low efficiency, uneven cleaning, and poor effect.

The wet cleaning method is mainly based on the principle of the electro-hydraulic hammer effect. The high-voltage pulse generator carries out interphase discharge through special electrodes placed in water, resulting in a large hydraulic impact. Because the surface adhesion of precision casting has elastic modulus and vibration frequency different from that of the casting itself, to achieve the purpose of sand cleaning. The cleaning effect of precision castings with complex shapes, such as a deep hole, blind hole, and inner cavity, is good. The surface cleaning method is the most widely used surface cleaning method for precision castings.

We are a leading and professional precision casting parts supplier, our products satisfy our customers. And we want to be your long-term partner, any interests, welcome to contact us.