އީމެއިލް ހުސް ނުކުރެވޭނެ

ޕާސްވޯޑް ހުސް ނުކުރެވޭނެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް މިހާރުވެސް އެބައޮތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް އެއް ނެތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

ހަބަރުތައް

Vacuum Plating Price v.s. Water Plating, Know Their Differences on Zinc Alloy Die Castings

Both vacuum plating and water plating are used in the surface treatment process of zinc alloy die casting parts in the die casting production process. Zinc alloy die-casting products are generally treated with appearance, because the processed die-casting products are more beautiful and wear-resistant. There are two electroplating processing methods for zinc alloy die casting parts, namely water electroplating and vacuum electroplating. The water electroplating process is suitable for zinc alloy die-casting products; it is mainly to put the electroplated products into the chemical plating solution for electroplating. Vacuum ion plating, also known as vacuum coating; suitable for zinc alloy die-casting products. Due to the cluttered process, high environmental and equipment requirements, the unit price is more expensive than water electroplating.

The biggest difference between water electroplating and vacuum electroplating is the price. The price of vacuum plating is higher than that of water plating. A brief overview of the pros and cons of both:

Vacuum Plating Price v.s. Water Plating

- If the first vacuum plating is not UV oil, the treated zinc alloy die casting has poor adhesion and it is impossible to pass the 100g test. From this point of view, the water electroplating process is superior to vacuum electroplating! Therefore, vacuum electroplating is required, followed by special spraying, so the cost is high.

- The color of water plating is monotonous, generally only a small amount of color, such as white chrome and black lattice, but vacuum plating is made of various colors due to post-processing.

- The general plating material used for water plating is "hexavalent chromium", which is a wrong environmentally friendly material.

What is the electroplating surface treatment process for zinc alloy die-casting parts, after the above analysis, I believe you have a certain concept of vacuum electroplating and water electroplating! Of course, this is to decide according to our intention and structure. plan. Yuge Die Casting Factory is a professional manufacturer of zinc alloy die casting parts and aluminum alloy die casting parts. For more than ten years, the company has been dedicated to die casting. The process from mold design to surface treatment is very complex, and then to useful and progressive die casting parts. Good production quality and low production cost!

Here is a brief introduction to its process:

Product appearance cleaning, static removal -> spray primer -> vacuum coating -> spray paint -> baking finish -> packaging. Vacuum plating can be divided into ordinary vacuum plating, UV vacuum plating and vacuum plating; the process includes evaporation, sputtering, gun coloring, etc.

Vacuum electroplating price v.s. water electroplating, process difference

The water electroplating process is relatively simple and does not require vacuum ion electroplating from equipment to the environment, so it is widely used. However, the water plating layer is defective and can only be plated with ABS material and ABS + PC material (the effect of this material plating is not very satisfactory). The temperature resistance of ABS material is only 80 °C, which limits its application scale. However, vacuum plating can reach about 200 °C, enabling the plating of components used at high temperatures. For air nozzles and air nozzle rings, PC material is required, and these components need to withstand high temperatures of 130°C. In addition, high temperature resistant parts are generally required, and a layer of UV oil should be sprayed during vacuum plating to make the product look shiny, high temperature resistant, and combined to ensure adhesion.

So what are the strengths and weaknesses of vacuum plating and water plating?

- Appearance treatment: In general, the substrate (plating) should be pre-treated by degreasing and dust removal before coating to ensure neatness and drilling of the coated parts, and to prevent defects such as pitting and poor adhesion of the primer Floor. For special materials, such as PE (polyethylene) materials, it should be modified to achieve the desired effect of the coating.

- Primer: When primer is used, the coating can be sprayed or dipped. The specific details should be determined according to the size, shape, structure and details of the user equipment of the coated parts and the quality requirements of the customer. Spraying method can be used, SZ-97T oil can be used; dipping method, SZ-97, SZ-97+1 and other oil can be optional, depending on the plating material. See the fit scale for each product in the product display.

- Primer drying: The coating oil series is self-drying paint, and the purpose of drying is to improve the production efficiency. Generally, the drying temperature is 60-70 °C and the time is about 2 h. The drying requirement is that the paint film is completely dull.

- When coating: When coating, make sure the vacuum degree of the coating machine meets the requirements, then heat the tungsten wire, and strictly control the heating time. Together, you should master the amount of metal coating (like aluminum wire). Too little can cause the metal film to hide the substrate. Too much, in addition to muck, will also affect the life and coating quality of the tungsten wire.

Conclusion

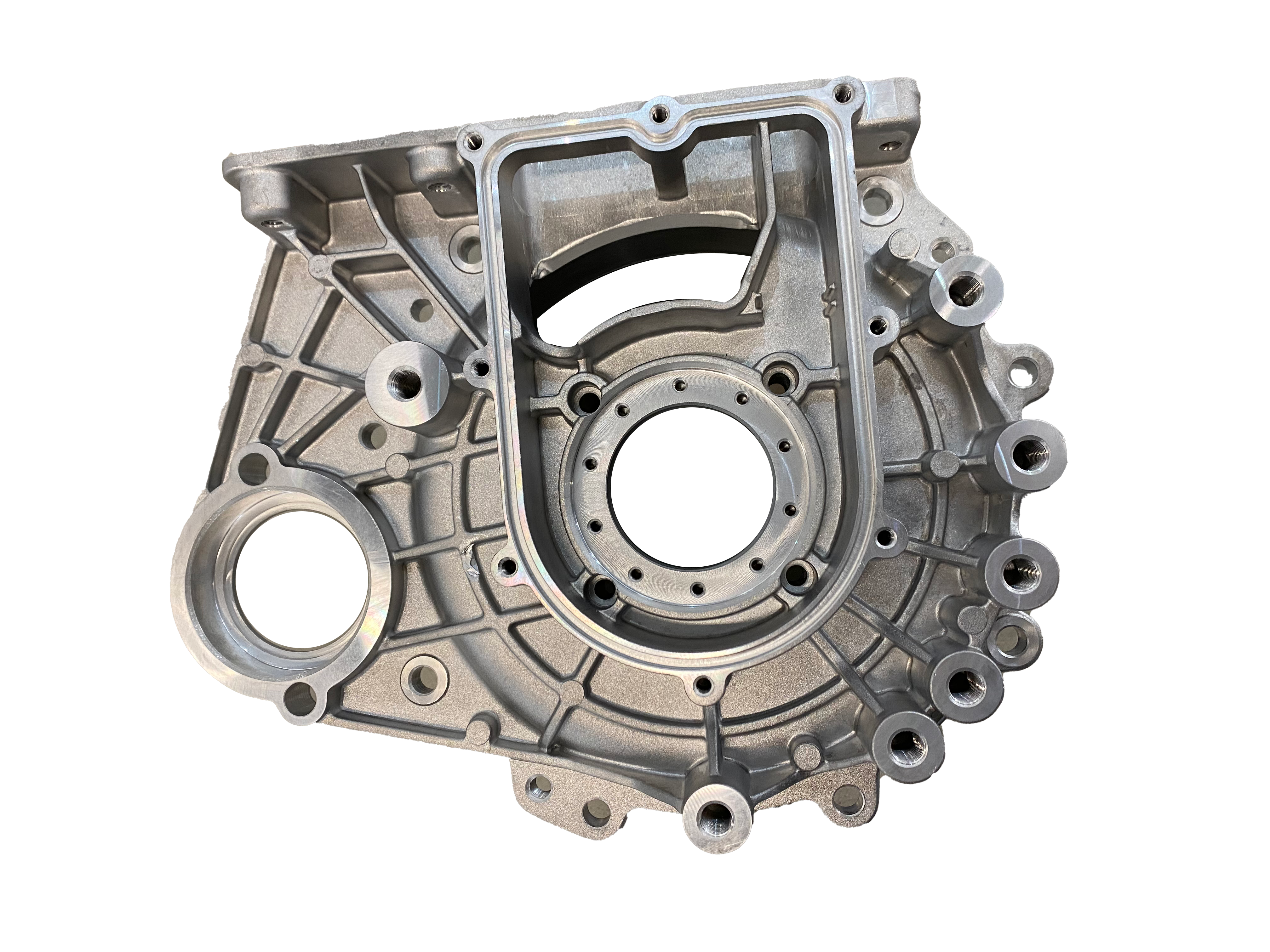

If you are looking for an automotive die casting manufacturers,auto parts die casting manufacturer,oem die casting manufacturer, we hope we will be your best choice.