އީމެއިލް ހުސް ނުކުރެވޭނެ

ޕާސްވޯޑް ހުސް ނުކުރެވޭނެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް މިހާރުވެސް އެބައޮތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

އީމެއިލް ފޯމެޓް ގޯސްވެއްޖެއެވެ

އީމެއިލް ހުސް ނުކުރެވޭނެ

އީމެއިލް އެއް ނެތެވެ

6-20 އަކުރު(އަކުރު ޕްލަސް ނަންބަރުތަކަށް އެކަނި)

ޕާސްވޯޑް އެއްގޮތް ނުވާތީއެވެ

ހަބަރުތައް

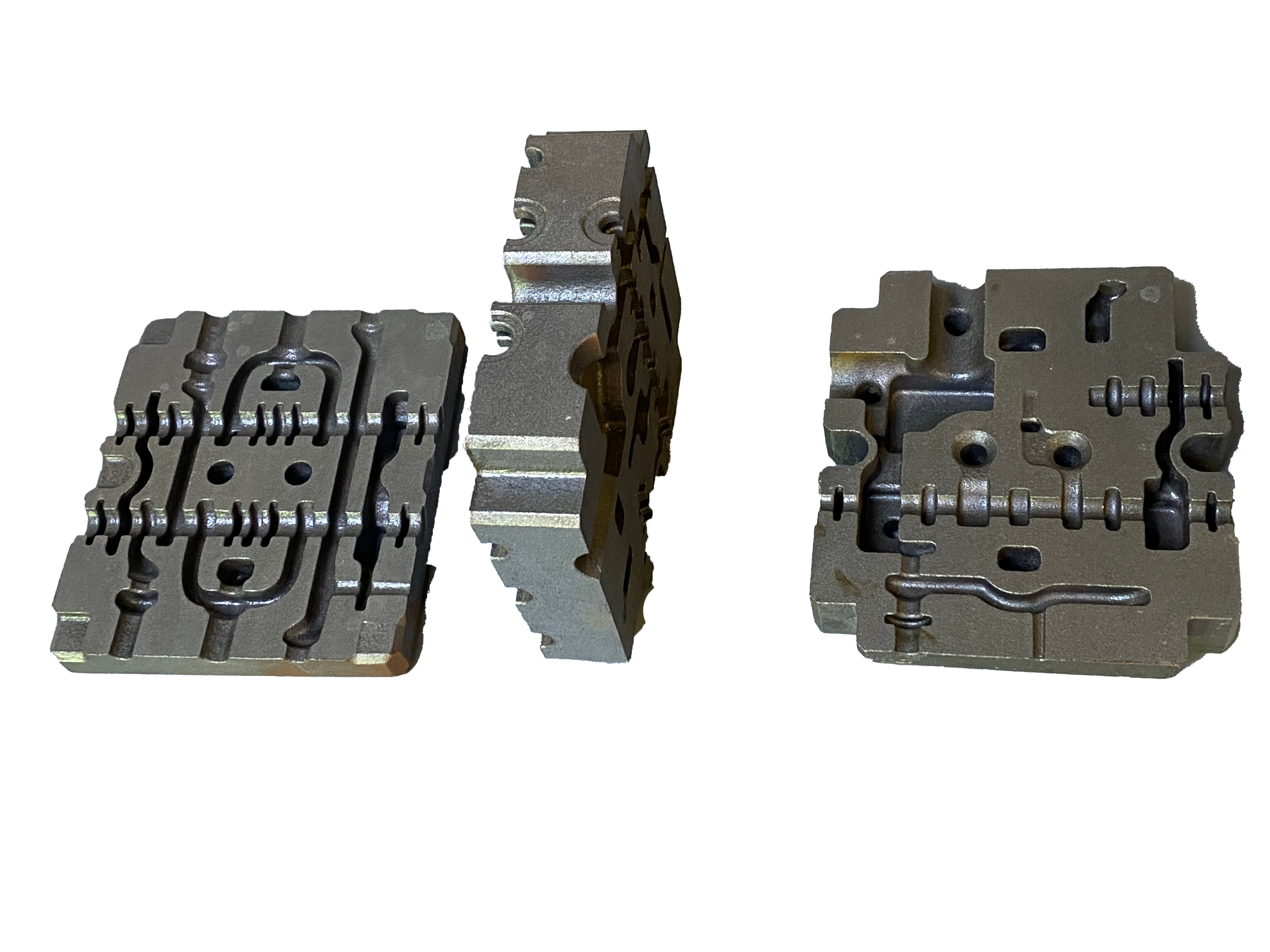

Common Welding Methods of Gray Cast Iron

Thermal welding method

Thermal welding is a welding method that heats all or part of the weldment to 600-700 ℃ before welding, maintains a certain temperature during the welding process, and cools slowly in the furnace after welding.

Features

When using the hot welding method, the weldment cools slowly and the temperature is evenly distributed, which is conducive to eliminating the white structure, reducing stress, and preventing cracks. However, the hot welding method has a high cost, complex process, long production cycle, and poor labor conditions during welding, so it should be used as little as possible.

The commonly used welding methods are gas welding and electrode arc welding. Cast iron gas welding wires, such as HS401 or hs402, are commonly used in gas welding, together with flux cj201 to remove oxides. The preheating method of gas welding is suitable for repairing small and medium-sized thin-walled parts. Cast iron cored cast iron electrode z248 or steel cored cast iron electrode Z208 are selected for electrode arc welding. This method is mainly used for repairing cast iron parts with large thicknesses (greater than 10mm).

The welding equipment of the thermal welding method mainly includes a heating furnace, welding torch, electric furnace, etc., and the welding process is as follows:

- Preparation and preheating before welding: remove the oil and oxide skin around the defects to expose the metallic luster of the matrix; For beveling, the general groove depth is 2 / 3 of the wall thickness of the weldment, and the angle is 70 ° ~ 120 °;

Put the weldment into the furnace and slowly heat it to 600 ~ 700 ℃ (not more than 700 ℃).

- Welding: use neutral flame or weak carbonization flame (do not make molten iron flow to one side during welding), and then melt into the electrode metal after the base metal is melted through; When white spots are found in the molten pool, stop filling the electrode metal, add an appropriate amount of flux, and then continue welding after removing the sundries with the electrode; To obtain a smooth weld, the weld after welding should be slightly higher than the surface of the cast iron, and the slag overflowing outside the weld should be remelted. When the temperature is reduced to a semi-molten state, the higher part should be scraped flat along the casting surface with welding wire.

- Cooling after welding: generally, it should be cooled slowly to room temperature with the furnace (generally more than 48h), or it can be covered with asbestos cloth (plate) or carbon ash to form a uniform structure of the weld and prevent cracks.

Gas welding

The flame temperature of gas welding is much lower than the arc temperature, so the heating and cooling of weldments are relatively slow, which is very beneficial to preventing the white cast iron structure and cracks produced during welding. Therefore, the quality of castings repaired by gas welding is generally better, because gas welding has become a common method of repairing cast iron.

Characteristic:

Compared with electrode arc welding, gas welding has high labor intensity, large deformation of weldments, and it is difficult to weld through when repairing large castings;

The quality of gas welded castings is good and easy to cut so many small and medium-sized gray castings in many factories are still more repaired by gas welding.

Precautions for gas welding operation:

- In the process of gas welding, neutral flame or weak carbonization flame must be selected;

- At the end of welding, the carbonization flame can be used to slow the cooling of the weld, which can reduce the burning loss of carbon and silicon, eliminate the over-thick oxide film, and prevent the white mouth from hardening;

- Oxidation flame can be used when eliminating the bottom of defects or beveling;

- During welding, the welding wire shall be added after the base metal is melted to prevent poor fusion;

- When it is found that there are small pores and white bright inclusions in the molten pool, a small amount of gas welding flux can be added to the molten pool to help eliminate flat slag, but the gas welding flux should not be added too much, otherwise it is easy to produce slag inclusion and pores;

- Properly increasing the power of the flame and raising the temperature of molten iron in the molten pool is conducive to the floating of gases and impurities, thus reducing pores and slag inclusions;

- During operation, it should be noted that the flame always covers the molten pool;

- When adding welding wire, always gently stir the molten pool with welding wire to promote gas and slag to float out.